NRCD - Direct expansion air conditioners

for high density racks with modulating compressors

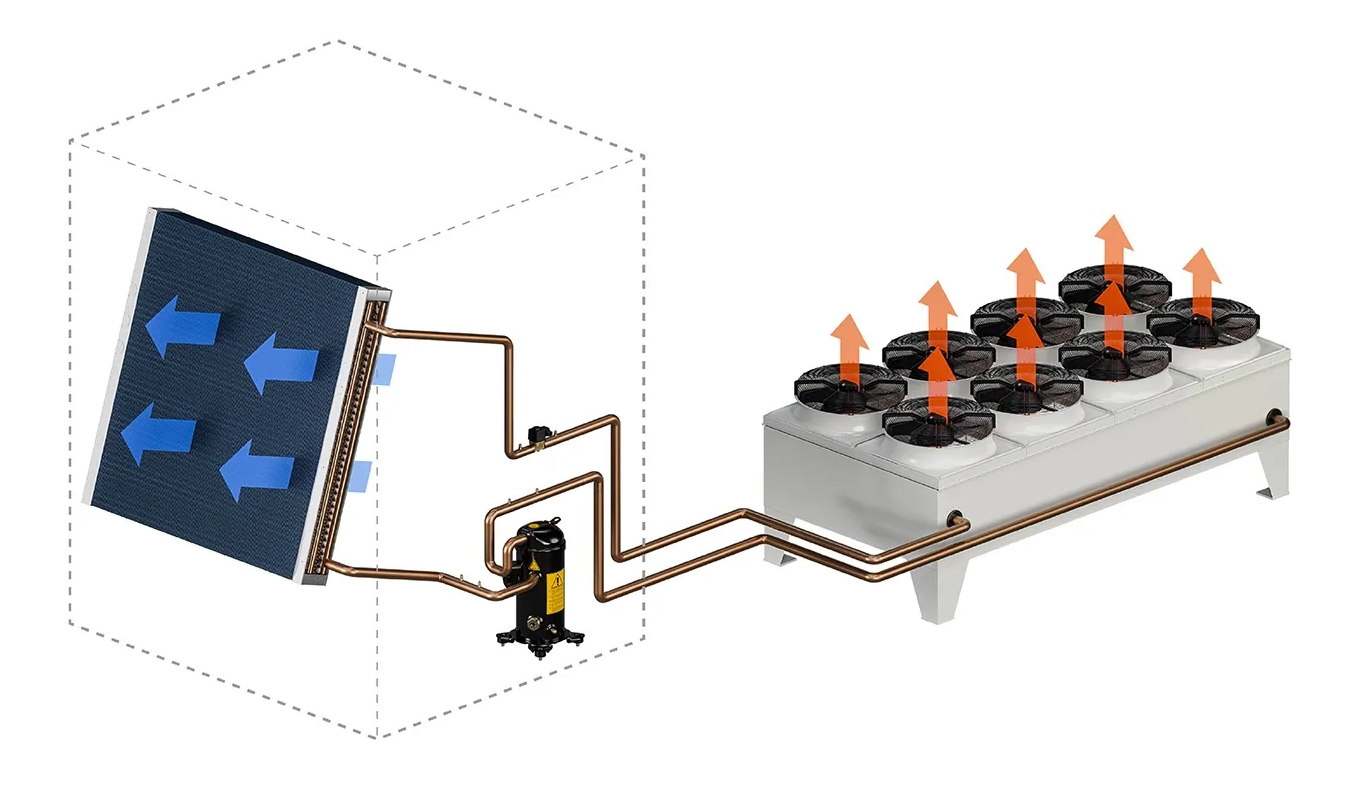

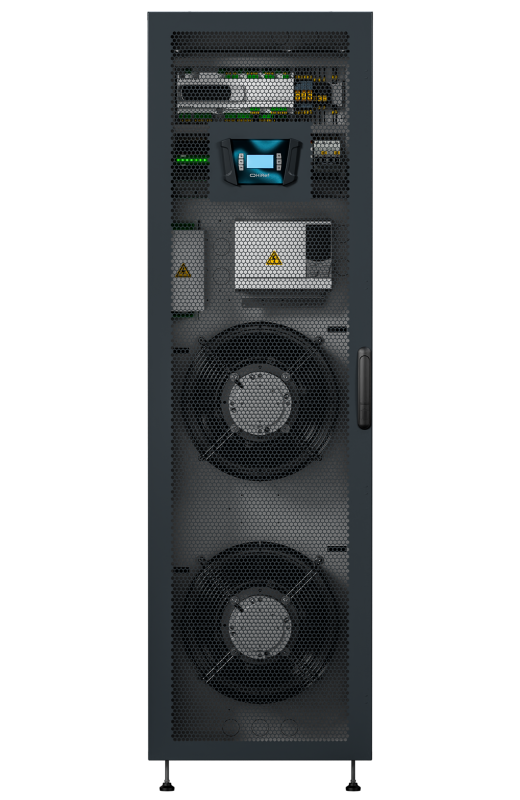

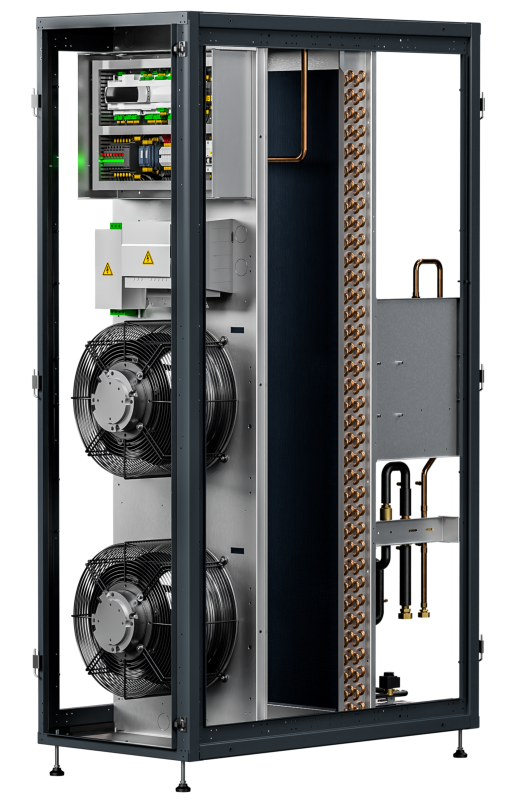

The rack coolers in the NRCD range are an ideal solution for the cooling of small-to-medium size Data Center racks where precision control of hygrothermal parameters is required 24/7. They are particularly suitable for small installations where a chiller cannot be installed or where water in the Data Center is not allowed. Internal design and component selection focus on the achievement of very high energy efficiency levels to minimise running costs of the entire system. NRCD units have an external remote condenser, which guarantees efficiency and reliability. In-Rack or In-Row configuration depending on how rack cooling is done - by creating hot and cold aisles in the Data Center via compartmentalisation and localised cooling - the NRCD range comes in two different configurations.

Technical data

- Cooling capacity: 12-50 kW

- Air flow: 2.700-9.000 m3/h

- Width: 300 / 600 mm

- System: Direct evaporation

- Refrigerant: R513A / R410A

Main advantages

Hot swappable fans

In order to minimize machine shutdown, a failed fan can be replaced without turning off the unit, thanks to the use of the protective basket and connectors for the power and control section. Fan replacement thus becomes a routine maintenance operation.

Safety in the server room

All models in the NRCD range feature heat exchange coils with hydrophilic coating. This special coating - together with adequate adjustment of air through-flow speeds - helps condensate collection during the dehumidification process, preventing any dripping on the inside and outside of the unit.

Ventilation EC

EC PLUG fans, standard throughout the range, are adjustable using different logics: flow rate, overpressure, constant ΔP and ΔT. Their accurate adjustment allows an efficient use of power for ventilation and a consequent reduction of the system’s PUE. Extended range speed adjustment is carried out via Modbus protocol. The “emergency speed” function allows for fan operation even in the event of microprocessor malfunctions.

Sliding control panel

For 300 mm wide structures, the electrical panel is designed to take up as little space as possible without interfering with air distribution over the whole working height of the unit. A “sliding drawer” structure has been used, making access possible during commissioning and extraordinary maintenance operations. This configuration also prevents tangling of the wiring.

High power density

The internal design and the special component layout allows for an evaporating coil with an extensive heat exchange surface area. The unit footprint is still small, ensuring optimal use of space in the server room.

Power modulation

The units adapt quickly to the Data Center’s cooling requests. Thanks to the inverter-controlled compressor, performance can be modulated to up to 25% of the rated value, thus reducing consumption. This ensures continuous operation of the unit even at low loads, without switching cycles on and off.

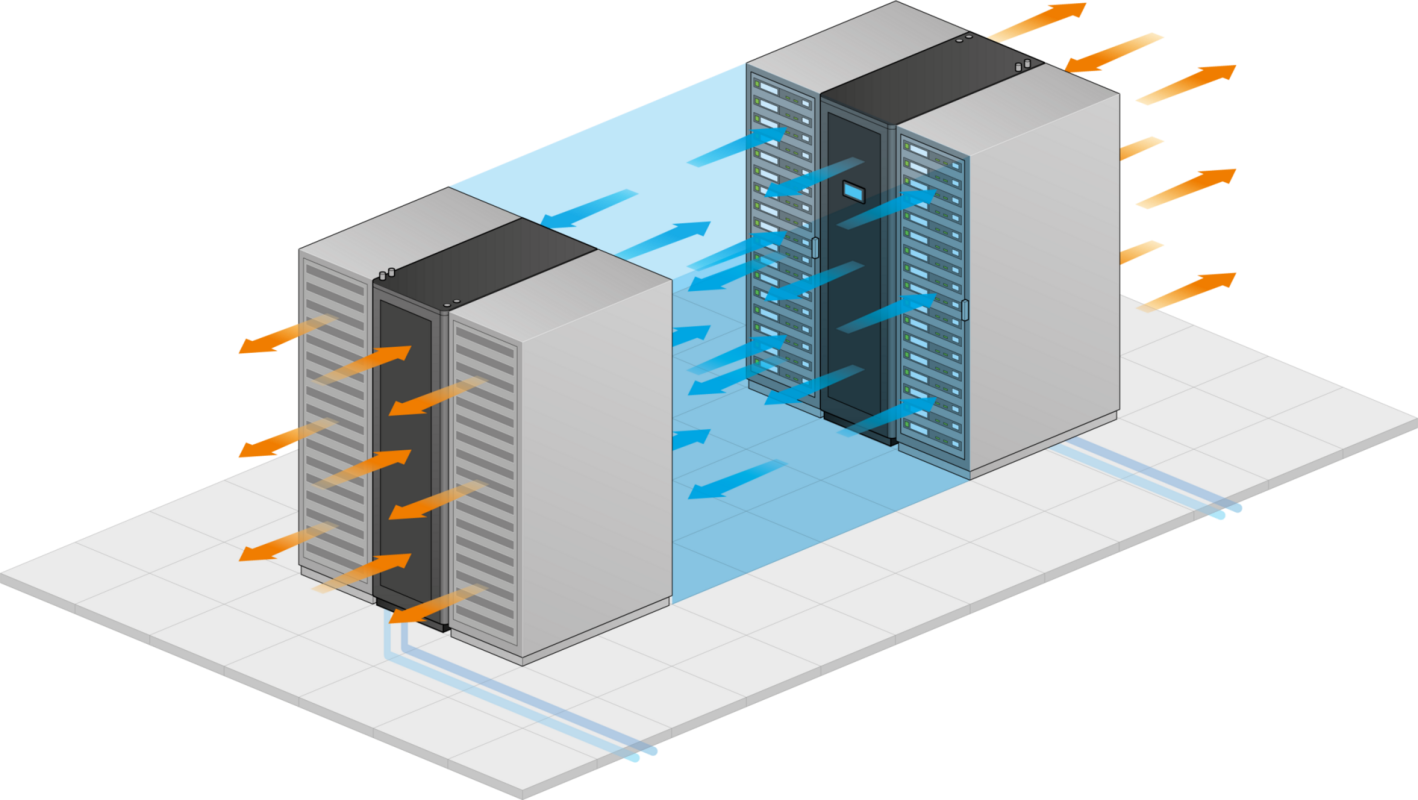

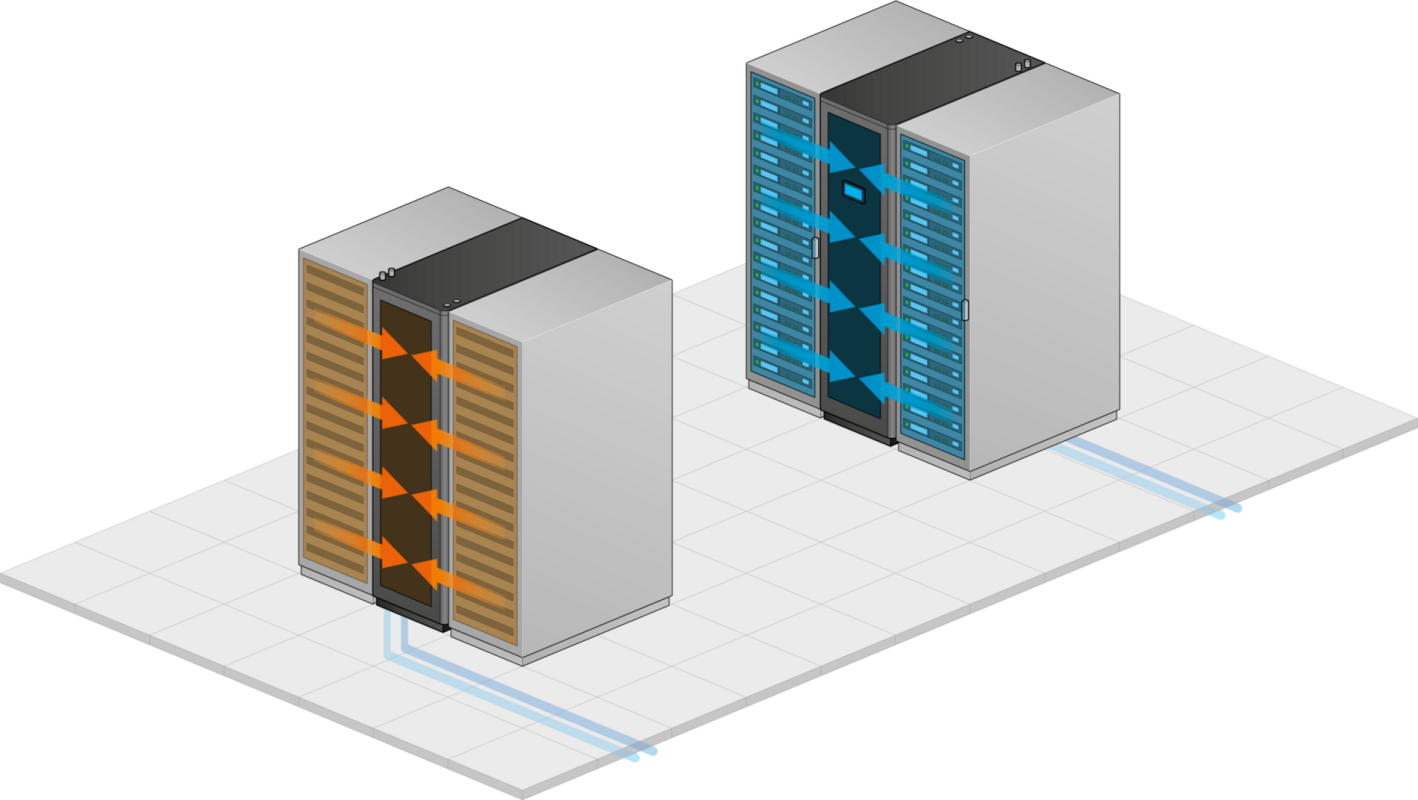

In-Rack or In-Row configuration

In-Row

Configuration that generates a closed circuit between rack cooler and rack cabinet. The air can be drawn in and delivered from the right, left or both directions.

In-Rack

Configuration in which cold air is released into the “cold aisle” to each rack cabinet, and hot air from the surrounding environment is drawn in by the rack cooler. The air can be delivered from the front, right and left.

Technological components

HiRef units can be integrated with the customer’s external supervision Building Management System (BMS), using the most popular communication protocols, including Modbus RTU, Modbus/IP, BacNet, LonWorks, SNMP.

The Modbus protocol, unlike the 0-10V signal, allows to not only control the speed of the fans, but also to capture, monitor and manage considerably more data and alarm information

Radial or centrifugal fans are characterised by backward blades. Air is taken in the axial direction, parallel to the rotation axis and delivered radially, perpendicular to the rotation axis. This type of fan does not require an external screw, has a high head and is suitable for use in indoor units where the air is often ducted and recirculated. They are driven by electronically commutated (EC) brushless permanent-magnet (BLDC) synchronous motors. The use of these motors reduces unit consumption, noise and footprint, improves the efficiency and life cycle of the system through accurate control of speed and acceleration, resulting in less heat dissipation. In addition, inrush currents and sparks are eliminated.

Scroll compressors include a mobile scroll, driven by the motor, which completes orbital revolutions and a fixed scroll that is coupled to it. The orbital motion creates a series of gas pockets that move from one scroll to the other. When moving closer to the centre of the scroll, where exhaust takes place, the gas is compressed to smaller and smaller volumes until the desired delivery pressure is reached. Scroll technology improves volumetric efficiency and flow continuity, reduces noise and leakage and eliminates harmful volumes and downtime.

Humidifiers are essential components for maintaining the right level of humidity in the server room and ensuring the proper functioning of the room equipment. Humidifiers with immersed electrodes can be installed in HiRef units, managed by proprietary software which, equipped with a special probe, keeps humidity levels at pre-established values.

Inverter-driven compressors allow compressor rotation speed and efficiency to be controlled, by modulating the frequency and the supply voltage of the motor. They are driven by electronically commutated (EC) brushless permanentmagnet (BLDC) synchronous motors. The use of these motors reduces unit consumption, noise and footprint, improves the efficiency and life cycle of the system through accurate control of speed and acceleration, resulting in less heat dissipation. In addition, inrush currents and sparks are eliminated.

Additional benefits

- Refrigerant R513A / R410A

- EC Fans

- Twin rotary and scroll inverter compressors

- Electronic expansion valves

- Advanced programmable microprocessor control with LCD display

- Humidity control through dehumidification and humidification

- Air filter class G3 supplied as standard Air Filters G4, M5, F7

- Double power supply with automatic switch Constant flow (airflow control) or constant available overpressure (ΔP control) ventilation modulation

- Low temperature kits for optimal operation in the case of installation in particularly cold environments