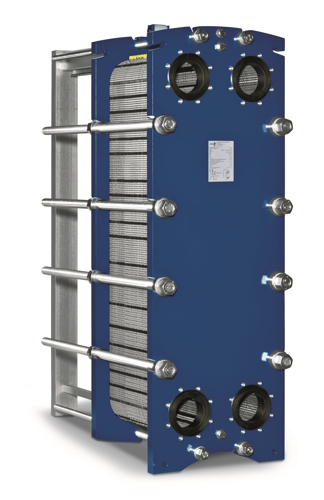

Plate heat exchanger

Gasketed plate heat exchangers, in 16 different sizes with nominal widths from DN32 to DN200. The applications of plate heat exchangers are diverse and can be used by our customers in the manufacturing industry, in the heating, ventilation, air conditioning (HVAC) market as well as in data centers and server rooms.

Both our standardized and our tailor-made solutions are particularly attractive because they have a high heat transfer rate and are inexpensive to purchase and operate.

We are happy to advise you on how this technology for heating or cooling can be integrated into your production process or air conditioning system as required and how it can be used.

Advantages

- Holistic planning

- Integration into existing refrigeration plants and industrial processes

- Fast ROI: Low investment, operating and maintenance costs

- High flexibility due to modular design

- Tailor-made for demand-oriented application

- High heat transfer rates

- Compact and powerful design

- Can also be used with aggressive media (e.g. salt water or sulfuric acid) thanks to various plate materials

- Low temperature differences due to innovative design

Plates

- Stainless steel 1.4301 (AISI 304)

- Stainless steel 1.4404 (AISI 316L)

- Titanium (Grade 1)

- Alloy 254 SMO (1.4547)

Gaskets

- NBR (up to 100 °C)

- EPDM (up to 150 °C)

- FPM (up to 185 °C)

Accessories

- Different connections in threaded and flanged design

- Cold insulation

- Thermal insulation

- Feet or fixing kit for floor mounting

- Condensate drip tray

- Counter flanges and screw set